ISO/TS 16949:2002 Linkage to the Core Tools

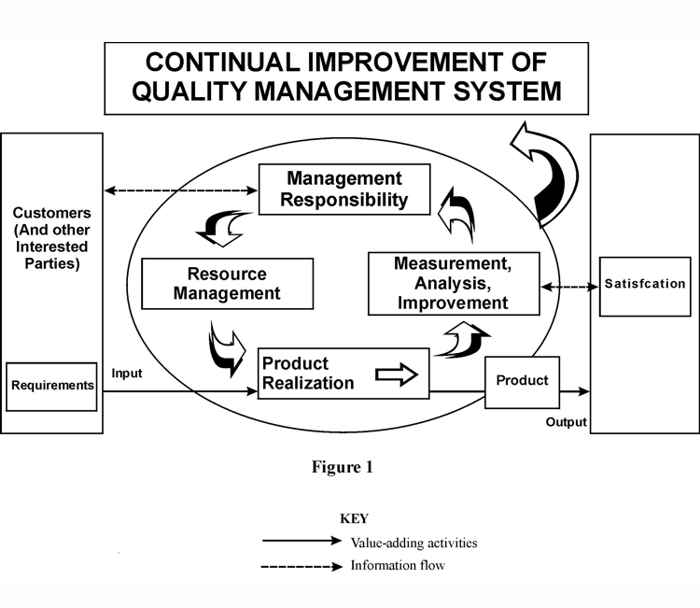

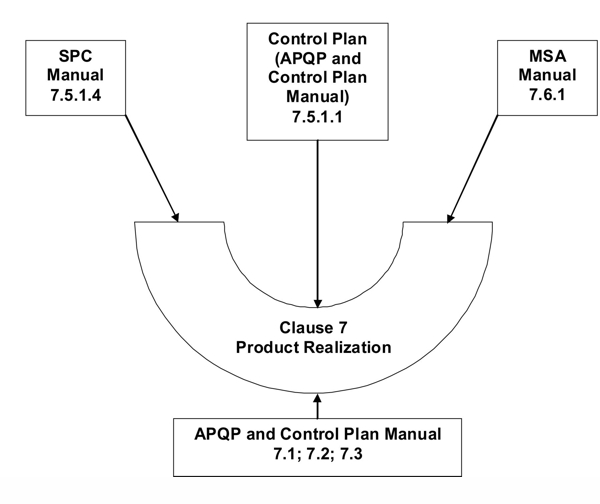

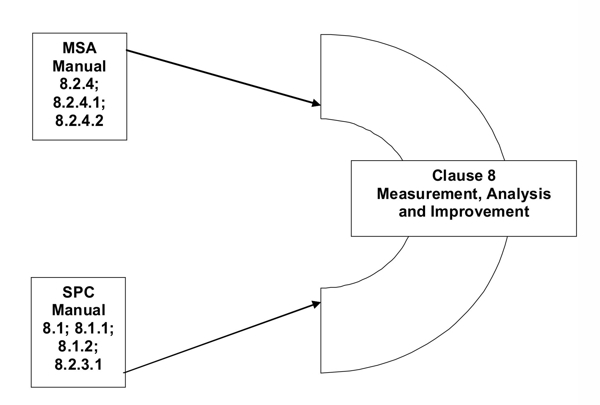

It is important to determine where the Core Tools (APQP, FMEA, PPAP, MSA, and SPC) are linked to the ISO/TS 16949:2002 standard. The following displays how these links are made in the “Plan-Do-Check-Act” cycle above. The following graphics display these links:

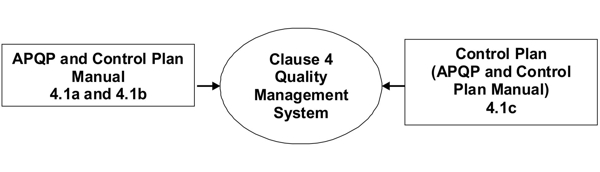

- The use of the APQP& CP manual establishes processes and their linkages as required by Clauses 4.1a and 4.1b.

- The continual improvement of the Control Plan ensures that the processes are effective in operation and control as required by Clause 4.1c.

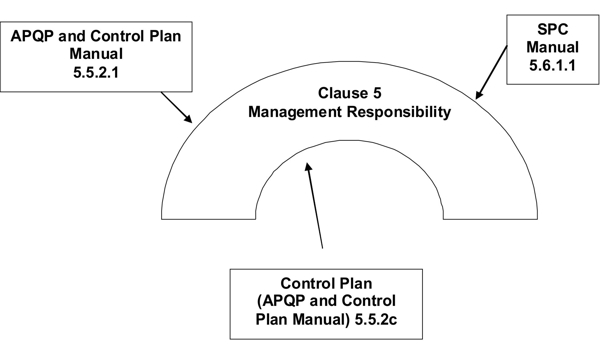

- The Control Plan is a sequential and exhaustive display of customer requirements. It enhances the Management Representative’s requirement of ensuring the promotion of the awareness of customer requirements in Clause 5.5.2c.

- The use of the APQP& CP manual allows customer representatives to determine if customer requirements are addressed. These include selection of special characteristics, setting quality objectives and related training, corrective and preventive actions, product design and development per Clause 5.5.2.1.

- The SPC Manual provides several tools to display performance trends that support the requirements in Clause 5.6.1.1.

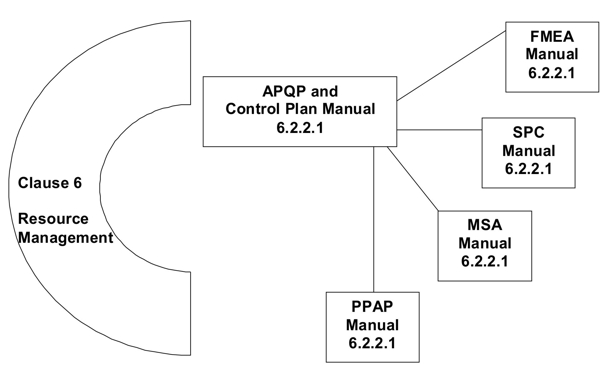

- Product design responsibility requires competence and skill in applicable tools and techniques such as APQP&CP, PPAP, MSA, SPC, and FMEA as required by Clause 6.2.2.1.

- APQP&CP provides tools and techniques for proper planning, customer-related processes, and design and development activities as required in Clauses 7.1, 7.2, and 7.3.

- The Control Plan is a highly structured sequential instruction of each step in a process as required by Clause 7.5.1.1.

- SPC techniques provide methods to determine preventive and predictive maintenance as required in Clause 7.5.1.4.

- The MSA provides tools and techniques that ensure the suitability of measurement and test equipment as required in Clause 7.6.1.

- The SPC Manual provides valuable reference to determine what tools and techniques are appropriate to assist an organization to meet the general requirements for measurement, analysis, and improvement in Clauses 8.1, 8.1.1, and 8.1.2.

- The SPC Manual also provides methods and tools to determine what an organization’s new manufacturing processes are capable of producing as required by Clause 8.2.3.1.

The MSA Manual provides tools and techniques that can demonstrate whether measurement devices are capable of verifying conformance to customer and product requirements.

"We are proud to provide services to the U.S. Government!"

"We are proud to provide services to the U.S. Government!"